Rammed Earth House Rauch

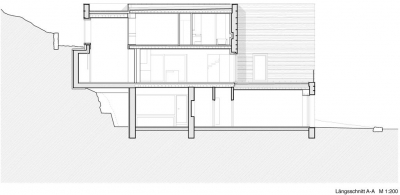

To bring the horizontal flow, the rocky homogeneity as well as the rough strength and compactness of the clay building technique in a spatial and an adequate formal architectural style was a huge creative challenge. The excavated material is transported from the site, the hook shaped incision in the earth has a geometrical pendant in the vertical and horizontal section and the naturally undulating flysch layers of the ground are transformed, and found again in the rammed earth walls.

In the beginning the loam excavated on the site was brought back into the building and sieved from 0 to 30mm then using processing techniques for many different functions, for example supporting walls, rammed earth oven, prefabricated walls, rammed earth floors and drainage. The walls were compressed in the formwork with pneumatic rams and rollers and are 45 cm thick and untreated. All walls at ground level are sealed outside with bituminous sheeting and foam glass isolation.

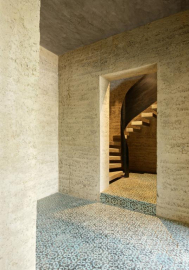

The 10 m high staircase is made in- and outside of rammed earth walls and is exposed by the light from a supported glass dome. The steps made of excavated loam blended with tuff lime are 9 cm thick, ground and fixed on the exterior wall to one side. The house is a result of the conviction that with natural building materials, a sufficient material quality and good manual experience, high quality building shells can be generated. During the two and a half year building time all applied material and operating data was documented and will be analysed and compared with realistic energy and climate data. A better part of the material and detail decision was completely new ground, starting with the geology of the building material and the use of instruments to define chemical adhesive and combustive properties.

From the earthy, raw atmosphere of the entrance level, one proceeds to the living level with its ivory shimmering rooms and waxed clay floors, a light casein priming on the window shutters and sliding doors, enhanced with the use of linseed oil and wax, as well as tactile, velvety clay render on the walls and ceilings.

This interior finish made of white clay and sand reinforced with flax fabric, contains wide damp register for the wall heating which has been mounted on an interior insulation made of cane, with a thickness of 10 cm. With the bedroom, working room and bathrooms the upper floor is held together by seamless rooms. The bathroom with the handmade ornamental ceramic tiles shows specific design qualities. All ceilings on the upper floor are made of rammed earth with integrated solid log floors made of local timber.

Windows and architraves are reinforced with trass-lime. Each ceiling has a circulating ring beam for the static stability. There is no foil or sealing foam used; only renewable insulation material and wind proofing with fine loam.

copy.jpg)

copy.jpg)