MO House

MO House

Systematic freedom

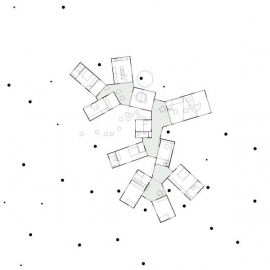

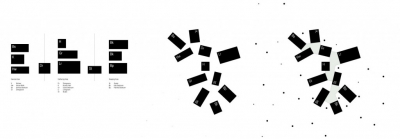

In 2010 we received a commission to design a single-family house in a forest in the outskirts of Madrid. Although the programmatic requirements were conventional, the site would demand a complex geometry. The powerful presence of the trees and the wish to have a house integrated in the woods led to a disaggregated solution. The program was transferred in a very direct and natural way to a number of simple rectangular pieces. The different topological relations between the pieces determined a series of useful solutions, 24 in the end. The optimal version was selected and the plan of the MO House was this way defined.

MO House belongs to a family of projects developed in the office beginning in 2005. These projects explore the possibilities of generating architectural complexity out of the combination of simple elements. The results produce nice surprises: combinations of a number of extremely simple spaces offer extremely rich spatial experiences. Some very simple basic rules and a series of elements with adequate proportions will result in an endless range of solutions.

Wood in the woods

The final arrangement of the MO House plan opened two technical issues to deal with. An elevated number of different angles in the joints between pieces and a penalized façade-volume ratio that would result in a negative impact on the energetic performance of the house. In addition to that, another key issue aroused: the proximity of trees required an unaggressive foundation system.

The technical solution adopted in a first approach steel skeleton with concrete slabs- did not seem viable. We needed a lighter system that could be assembled with the highest possible accuracy. It had to be simple like the plan- and have a top thermal performance. On a visit to his studio, a friend showed us a structural system that was new to us: cross-laminated solid wood panels by KLH. The product met all the requirements: a solid structural material with high insulating performance and CNC geometrical control manufactured at their Austrian factory. The house would be solid wood. Wood in the woods. 72 mm thick walls. Slabs from 95 to 182 mm. The total weight of the structure would not reach one third of a conventional system. The foundations could therefore be made of galvanized steel micropiles only 2 meters deep. The panels would be manufactured by numerical control cutting, ensuring accuracy at all angles. The structure would be insulating, continuous, lightweight, precise and extremely thin. The floor of the house could be a direct transposition of the work scheme. The installation process would be fast and accurate.

The nature of the project remained intact and its technical requirements had led us to the discovery of a new field of project possibilities.