Fallahogey Studio

Fallahogey Studio creates an understated, inspiring and motivating workspace for a young ambitious international architecture practice. The new studio permits the growing team to continue their award winning work in their preferred rural location, sustaining their role within the local community.

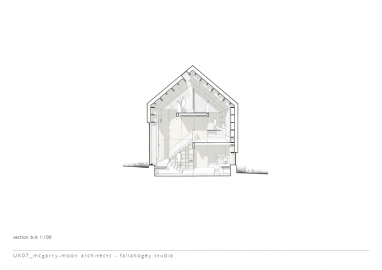

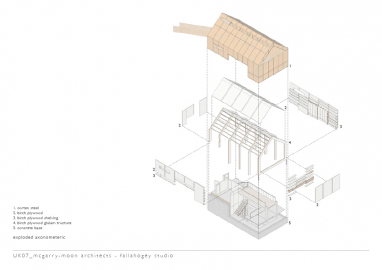

Located within rural Northern Ireland in the grounds of the directors’ family home, the restrained pitched-roof silhouette of corten and fair faced shuttered concrete studio salutes the agricultural structures of the area whilst hinting to the dynamic space within. The frame was fabricated locally off-site allowing for precision and quick assembly. All materials were sourced locally and the skills of local tradesmen utilised, allowing for controlled management of a time sensitive programme and conservative budget.

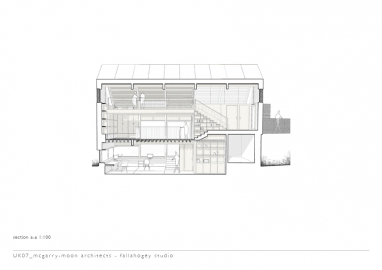

Stringent planning parameters required a cohesive understanding of policy to enable the realisation of a contemporary build within the sensitive rural setting. Materiality, scale and sighting were critical to planning permit success. Proximity of the site to Fallahogey House resulted in potential privacy and dominating issues to be strategically designed out. Topography was utilised to nestle the studio among the existing apple trees whilst further sinking the lower ground level of the studio into the land allowed significant reduction of height impact and eliminated all privacy issues. The conservative budget had an impact on the design and construction process. Accommodating the multiple functions required by an architectural studio within a small and controlled footprint was essential. The form and footprint although small and simple holds a series of bright intricate spaces, serving the various functions.

Agricultural materials of corten steel and fair-faced concrete were utilised for their affinity with the local area, longevity and low maintenance properties. The studio design was based on the dimensions of plywood and corten sheets to ensure minimal wastage. The primary structure of birch plywood glulam, from renewable sources, doubles as the interior fit out reducing cost significantly. The frame was fabricated locally off-site with all dovetail joints, allowing for quick and simple assembly and serving to keep costs low. All trades involved in the construction of the project were local and material was locally sourced, cutting down on the carbon foot print/embodied energy during construction and increasing social sustainability. The building is insulated to the highest level, triple glazed and designed to capture maximum but controlled solar gain thus the building requires little heating.