Campus Restaurant and Event Space

This pavilion provides a new central cafeteria and event space for Trumpfs Stuttgart-based industrial campus and headquarters. It is the new social center for the company for both blue and white-collar workers.

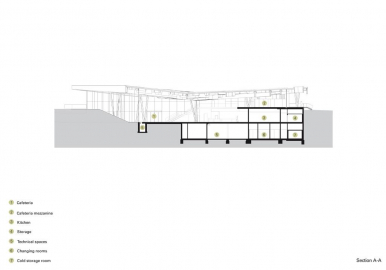

As part of a park entrance sequence, it is located between the gatehouse entrance and the A81 autobahn. As a geometrical extension of the existing customer centers ground level and placed along the autobahn, the pavilion helps form a courtyard entrance for Trumpfs visiting customers. The pavilion with seating for 700 enables the companys 2000 employees to lunch around three time slots in the large central space with reserve seating in a mezzanine. When programmed for events the space functions as an auditorium with seating for 800. The canopy roof of the pavilion hovers over a large excavation, positioning the main level at 4 meters below grade.

This height is determined by the tunnel level of the campus, an infrastructure system that connects all buildings on campus for moving goods and personnel. The pavilion can be entered either from the tunnel level or from above.

This results in forming an amphitheater-like space: the main level extends beyond the glass facades, which are then framed by berms at grade. The mezzanine level, arrived at by way of two pre-cast concrete stairs, compresses the spatial experience under the roof. Below the mezzanine level is a large service kitchen and loading area. Technical spaces and storage are located under the main dining level. The intention of the roof was to create a polygonal leaf-like canopy that achieves long spans over groups of columns.

This structure combines a steel frame and columns with a glue-laminated wood-cell infill. The steel frame consists of 9 triangular fields, which are placed on 9 column groups.

The columns are located away from the beam perimeters and intersections to enhance the hovering affect of the roof. These columns are splayed to provide stiffness and stability while using as little steel as possible and remaining light.

A cast-in-place concrete elevator core offers additional shear. While the steel allows for large spans, the Glulam infill was chosen for its workability and as a sustainable material. The wood cells are functionally coded and constructed either as skylights with solar-glass, perforated wood acoustic planking or as artificial lighting cells.

In order to economically achieve this complex structure we employed CNC routing and sawing to construct the more than 300 unique honeycomb joints. This is a particularly exciting development where mass-customization is becoming economical and fast. We believe that engineered timber is one of the best new materials for sustainable construction.

The enclosure of the pavilion is achieved by a glass façade. A vertical barcode-like series of tapered steel fins provides support for solar glass. Sun screening is further improved by a series of rolling screens. The facade framings are detailed at the head with a syringe-like connection, which allows the facade to move independently from the dynamic roof movement. Closed facades at the exterior are clad in custom-fabricated ceramic tiles.

copy.jpg)

copy.jpg)

.jpg)

.jpg)

.jpg)