Summer House, Storfjord on the West coast of Norway

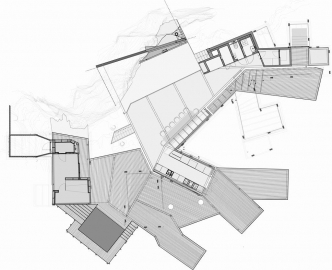

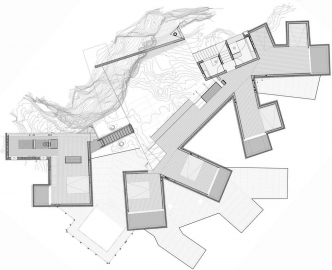

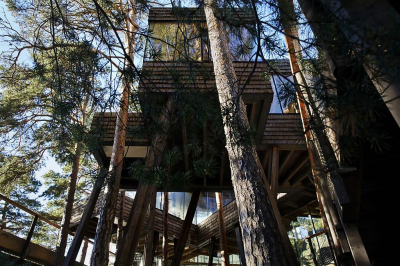

The site is a separate plot that was designated for a summer house many years ago. For different resons it was not sold until a few years ago. There is no road to the site so only light machinery was used and the site was changed as little as possible. The main level contains the common rooms. A part of the rock wall behind the house is inside the living room. The bed rooms are placed on the upper level, between the pine trees. Terraces are placed between the trees at various places, giving sun at different times of the day. During the building process we ended up using hand drawings, or a mix of CAD and hand drawings, because of the unmatched efficiency of this type of drawing production. The foundations are thin steel rods (ø25mm) that support hinged wooden pillars. In this way we could avoid all roots, and had established a robust static system that would be stiff in any configuration we would need.

The foundations are of two types; bolts drilled directly into the bedrock, or concrete walls, placed directly on the bedrock. Together with the surveyor we marked out all the points on site and indicated the different dimensions. It soon became clear that several of the holes had to be moved because of loose rock, important roots, or pockets of soil. We had anticipated this situation so the foundation system was designed in order to handle both large deviations and tolerances.

The pillars are glue laminated wood, delivered precut. The steel parts where produced locally. Two and two pillars form an A. Onto these horizontal prefabricated glue laminated beams were hoisted, with a small winch placed on the top of the A-pillars. The secondary structure is mostly made from high quality pine (veneer quality). A large amount of different profiles were produced, according to what was the most efficient structure in each case.

The heaviest elements are the steel beams in the ceiling of the living room. They turned out the way they did because we had already purchased the steel earlier in the project to use as columns. As the height of the house was adjusted for various technical reasons, the original steel profile became too small. We could of course send the steel in return, but it was economical to use material that we already had and it was a nice architectural and constructive challenge too.

It was not necessary or even economically possible; to continuously update the main drawings. The whole project is after a certain moment only described as parts of a puzzle. These parts fit together on the site, but not on paper.

We would like to question the ease with which architects, and society in general, uses violence to a site, in the form of large machines and explosives. We think that simple strategies and the conservation of topography and vegetation are aspects of sustainability which deserves more attention.