Summer House

The clients wished for a building where the landscape would be strongly present. The glass pavilion is a small building (90m2), designed for the needs of two adults allowing them to enjoy the summer in the midst of the ever-changing scenery.

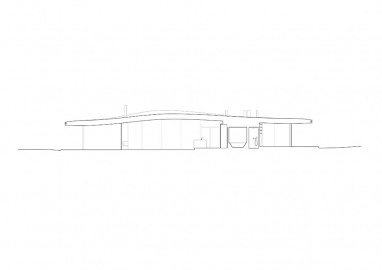

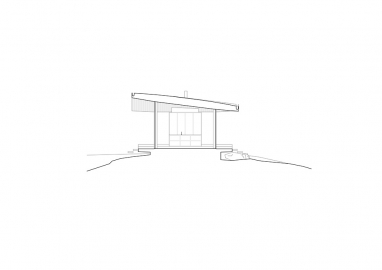

The site is beautiful - laying on a hilly, smooth rock, nested in between the border of the pine forest and the open sea. The vegetation around the pavilion was preserved utmost close to the original state.

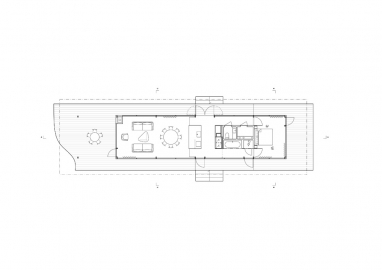

The narrow building mass is placed in parallel with the shoreline in order to create a protecting wall against the predominant wind direction. Long eaves connect the indoor with the outdoor and protect from the sun and the rain. The altering roof shape and the floor levels follow along the shape of the natural rocks. The materials are adjusted to the surrounding nature. The facades are glass, copper and painted metal. The terrace is in-situ concrete and wood. Oak, steel, limestone and copper are utilised indoors.

The clients’ wish of a small building differs delightfully from the dominant trend of the past decades: making the free-time dwellings increasingly large in size, well-equipped and inhabitable through-out the year. The pavilion in question gave an intriguing chance to make a modern interpretation of the simple Finnish way of life; living according to the seasons.

Clear, but unusual concept caused a lot of custom-work in the design of the details and structure. Even though the building is designed for summer-time usage, it also has to bear the harsh winter conditions of the site. The extreme changes in circumstances require strong durability from the structure and materials. In addition, easy maintenance was requested. Building codes posed challenges for the design and realisation of a building that deviates from the mainstream.

The pavilion is designed for unique needs. Handcrafting was used in exceptional amounts compared to the norm of the current Finnish building industry. The execution in collaboration with a local contractor succeeded beyond expectations.

The base floor construction was realised by a heavy double extruded plate. The structure enables locating the floor surfaces close to the rock, adequate heat insulation, heat movements, floor heating and keeping the surface plate dry.

The load bearing frame and its bracing are a combination of steel and wood. The massive coastal wind loads combined with the desires of the shape of the roof, the thinnest possible exposed structural frame and leak-proof glass wall elements, created tight transitional borders for the frame, and as a consequence, the complexity of designing the steel frame increased accordingly. The solution was a steel frame bend to the final shape of the roof connected to a plate made out of plywood and laminated wood. The load bearing part of the cantilevers of the roof is also laminated wood.

The high level of prefabrication and the strict dimensional tolerances made the fabrication on the steel structure demanding. The visible steel pillars were made of rolled steel sections and plates welded onto them. Every profile and plate-pair was chosen one by one according to the dimensions of the profile.

The building is heated with geothermal energy.