Tiwag KWB Control Center Silz

The Tiroler Wasserkraft AG (Tiwag) operates most of the power plants in Tirol, the Sellrain-Silz Group at the upper Inn Valley is one of the largest one. In search for a new building for the control center to meet the latest safety standards the Tiwag has launched a european-wide competition 2011, which was won by Bechter Zaffignani Architekten.

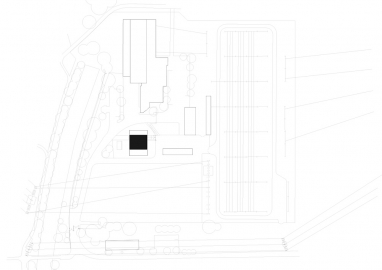

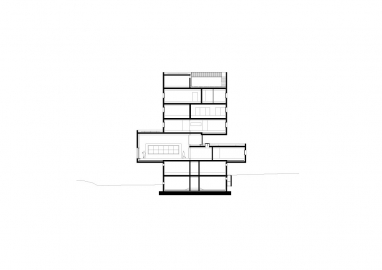

The new building for the power station control centre in Silz is a massive, tower-like, free-standing building. The dominant building on the site was and still remains the old turbine building. Various additions reduced the impact made by this building, with the result that the high-energy processes on the power station site were no longer externally legible. Through the formal idiom it employs the new building attempts to depict these processes. In terms of height, width and axial orientation the new building relates to the turbine building. Its shape takes up and continues the existing spatial direction of the turbine building. A new, clear and expressive volume is made that conveys a sense of the energy processes on the power station site. The control centre now marks the spatial centre of the power station site and connects the neighbouring volumes to create an urban structure.

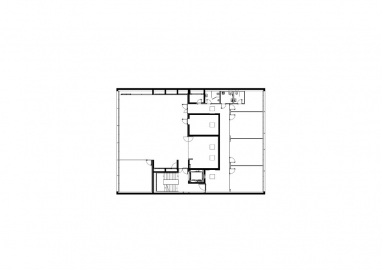

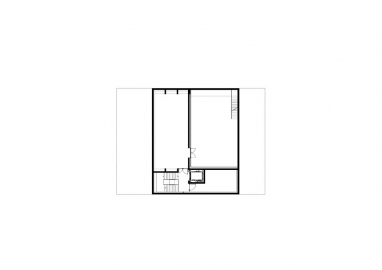

The idea behind the control centre is based on stacking the individual functions vertically, with each functional unit organised on a separate floor level. This clear hierarchy simplifies the administration of the access and security areas and allows a linear networking of the infrastructure. In terms of the amount of space needed the control centre area with the control room is a special case. The need for extra height in the control room allowed the development of an expressive and yet logical building volume. The building’s emphatic verticality is given an additional horizontal moment and creates a powerful gesture towards the north. In response to the user’s requirement for glare-free offices, the east and west facades have no openings. These solid panels form a load-bearing external envelope that is thermally detached from the internal walls and the floor slabs. The solid concrete parapets on the south and north facades function as upstand or downstand beams and serve to structurally strengthen the floor slabs. The connection between the internal and external construction is made by means of stainless steel inserts and stainless steel shear dowels.

The materialisation and the colour of the new building relate to other structures in the area of hydraulic engineering. Concrete is the ideal material for providing sufficient resistance to the enormous force of water used to generate energy. Like no other material it conveys a sense of security and longevity. The brown colour of the smooth exposed concrete surfaces – achieved by the addition of iron oxide pigment – refers to the dynamic components of the generation of power. Pressure pipe lines, turbines and transformers are all made of metallic materials produced from iron ore.