Drawing Studio

A dedicated Drawing Studio for Arts University Bournemouth where students from all 17 Departments ranging from drama, film, architecture, graphics etc. can make hand drawing : seen as a fundamental mode of creativity – even in an Institution with extensive digital involvement.

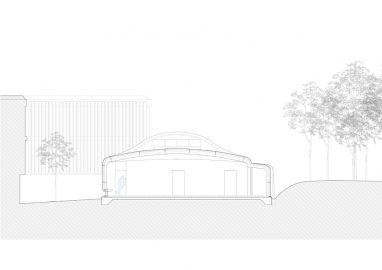

Located in a corner of the Campus close to the Exhibition Gallery and alongside a bank of ‘characteristic’ Bournemouth pine trees. Provocatively bright blue on the outside and entirely white on the inside. Of ‘monocoque’ construction from prefabricated steel sheets with a GRG interior surface. It has already become a virtual Icon for the AUB and is the first such dedicated stand-alone Drawing Studio to be built in a British art college for more than 100 years.

The project is entirely based upon the simple intake of natural light and lack of distraction from within – except for the tops of the pine trees. The detailing is kept to a minimum with careful thought given to every junction so that there is nothing to lure the eye away from a drawing in progress.

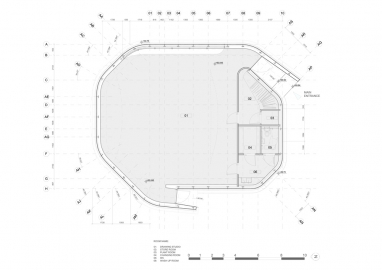

There are 4 different types of light. The main oval north light has a ‘booster’ clerestory north light that bounces light from the back wall. A thin window strip under the bench introduces a ‘mysterious’ additional light source and from the glass main door, some ‘washed’ light proceeds from the curved corner.

The Drawing Studio responds to its natural surrounding consisting of flowing grassed mounds and a dense group of trees. The landscape scheme focused on preserving and restoring the site’s natural habitat and enhancing the existing contribution which the trees made to the campus.

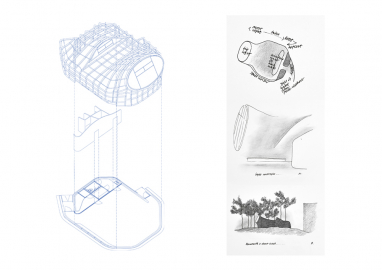

The design for the Drawing Studio incorporates a holistic approach to sustainability. The naturally ventilated building directly faces north and its large windows allow maximization of the use of natural daylighting. The building has a simple material palette of 17 prefabricated steel monocoque sections, Glass Reinforced Gypsum panels and glazing. The seamless monocoque structure creates an airtight construction so reducing the building energy use.

The project makes use of new geometric modelling tools, buckling analysis and steel fabrication techniques, which take an existing technology and, through the use of more sophisticated automated tools, achieves much higher levels of precision and refinement in the final form.

The development of these tools has allowed the use of the structure as a finished architectural form, eliminating the need for a separate applied cladding layer and reducing the amount of material, effort and capital investment. Innovation through the integration of building components, which are usually designed separately by different disciplines, has the potential to create more holistic, coordinated and sustainable designs.