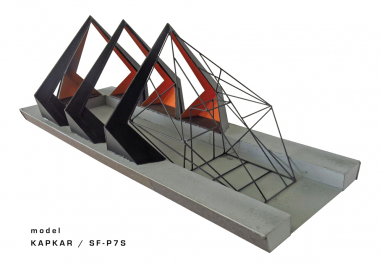

KAPKAR/SF-P7S

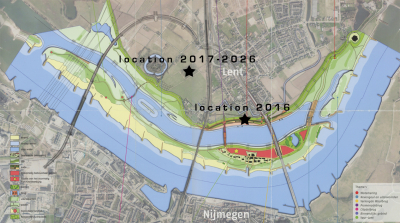

KAPKAR/ SF-P7S is a relocatable pavilion for a programme of performances, debates and presentations suited for up to 50 persons. It has been designed to use during Bouwlab, a ‘place-making event’ at a new waterfront in Nijmegen. The event was set up to experiment with new and sustainable forms of building and living. In 2017 it will be relocated.

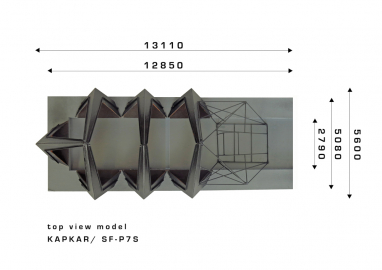

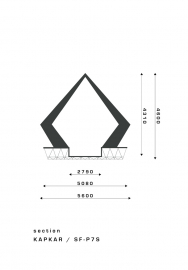

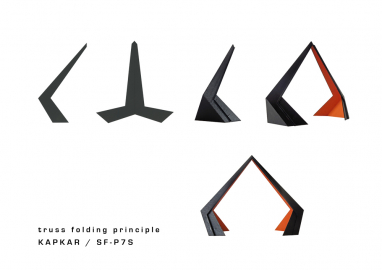

Starting point is the box-frame truss, an assembly of beams that serve as the construction frame for a farm building. In the design, I translate this into a contemporary version, giving new meaning to the gable roof in the landscape. The supporting construction, which is normally on the inside of the building, was moved to the outside in order to reveal it as an integral part of the roof and the walls. The structure is a hybrid result of different building methods. The centre of the design are three pairs of principal rafters that have been placed on a wooden base with a seventh perpendicular principal to close the construction. The principals were inspired by the classic saddle roof truss that I unfolded and transformed to create a new type of principal that constitutes a small space in itself: inside the pavilion the principals open to form intimate alcoves that can seat three people.

The first problem I encountered was the limited amount of time of four months to realise the project. Permits and sufficient funding had not been secured yet. The realisation budget of €35,000 for a wind and waterproof building that can accommodate 50 persons was extremely limited. The third challenge arose when I was asked to collaborate with MCT, a company that has developed a new construction system called KNØP. Combining custom-made elements with a specific construction system led to numerous challenges. The fact that nothing could be embedded in the ground on top of the embankment was a further limitation. The way to deal with all these challenges was to execute the entire process ourselves. By building the design ourselves we avoided interference and profit margins of middlemen like contractors. This direct approach allowed us to realise things that would have been unaffordable otherwise. The project was partly built in a warehouse belonging to the client. This way, they were constantly aware of what was happening and they were directly involved in decisions regarding things like material and use. It was very efficient to have such short lines of communication.

The principal rafters were made of plywood treated with a water-based rubber roofing. The wooden deck of Douglas boards is lined on a steel-wire base of MCT company who used this project as a pilot to experiment with their sustainable new unfolding rapid construction system. Douglas was selected because it is a sustainable product that doesn’t need additional treatment and its beautiful aging process. The building consists largely of roof plane. This refers to the rural architecture from the surroundings. Given the limited budget, the choice was to use materials that did not cost more than €10/m2. Galvanised corrugated iron sheets fit this concept perfectly. This simple material is slowly disappearing from the Dutch landscape. I find this regrettable; the material is very beautiful, and I took this opportunity to create contemporary architecture using corrugated iron. A transparent variant was chosen for the lower parts allowing lavish daylight to enter. The structure can be placed without foundation, is low-maintenance and has low environmental impact. It consists of 15 parts that can easily be moved by a small crane. Total costs € 35.000,-