Waste Thermal Treatment Plant

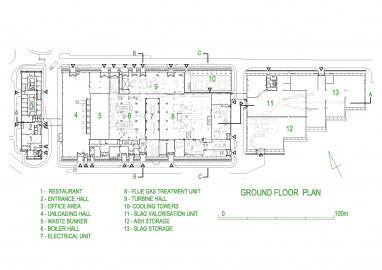

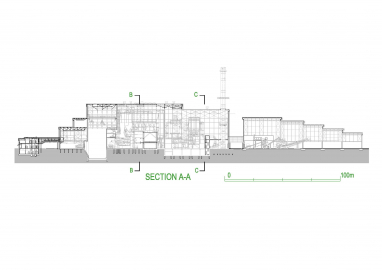

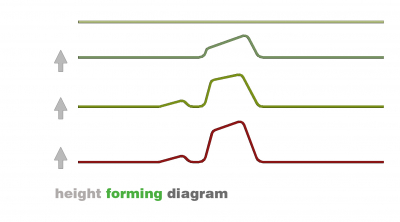

Waste Thermal Treatment Plant in Krakow is interconnected building complex, 300 m long and 80 m wide with a height of 40 m. The huge building body is divided into segments, each of a different height that increases according to functions and technological needs, with the boilers in the highest part and slag and ash management section at the end of the complex.

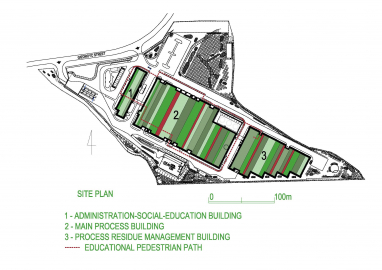

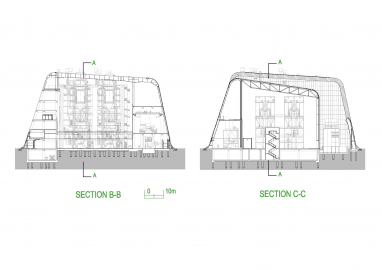

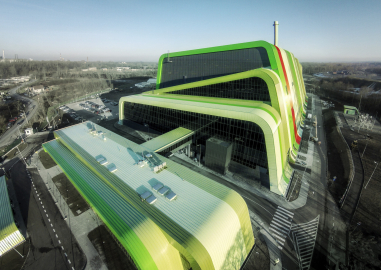

The Waste Thermal Treatment Plant along with technical infrastructure is localized at the Giedroyc Street in Krakow. The spacial complex of the Plant consist of three buildings. In the front section of the plant, there is the administration – social - education building located. The biggest object is the main process building located in the middle of the complex. Process residue management building closes the urban layout of the entire plant. All the buildings are interconnected by enclosed link bridges. The linear building complex is complemented by two canopies. Every building consist of several segments which are differentiated at height, separated across the longitudinal axis of the complex. Multi-colored aluminum sheet cladding is the most characteristic element of the building complex. It was inspired by linear shape of fields and the coloring of folk costumes.

The main design goal was to fit all necessary technological functions inside the collective architecture body of the plant and get strong connection between the buildings and the landscape and the environment. The unusual cladding significantly reflects the diversification of internal cubature of technological equipment and complexity of the process. It serves two functions: to provide optimal conditions for the service, maintenance and operation of the process and to create a single, environment friendly shape of the object, blended into the landscape. The Plant’s form is a continuation of the expressive modernism architecture, a slightly different emphasis on the well-known maxim "form follows technology and context". The plant is open to visitors, who can follow an educational path through all utilization stages and learn that energy released in the combustion process is transformed into heat and electric energy. The Plant is located in the area potentially threatened by flooding. Two main buildings are protected by internal flood resistant walls located along the external walls. Gates and doors are equipped with automatically closed bulkhead system.

Difficult soil and underground water condition determined selection of foundation solution. All buildings are constructed on reinforced concrete piles with length of 6-15 m. Main structure of the buildings has been designed in mixed structure: reinforced concrete and steel. Basement section, 9 m deep waste bunker, main columns, slabs, staircases, fire partitions are made of reinforced concrete. Assembly works of two incinerators has been proceed before closing the main boiler hall by external cladding. The structure of cladding is steel braced frames consists of steel roof girders and vertical and sloped columns supported on reinforced concrete columns. Multi-color aluminum cladding covering all segments are made of standing seam panels. Contractor challenge was to transport to the constructor site and assembly 36 m long aluminum façade panels. The panels’ length was determined by necessity of minimize the number of joint points. Transparent and partially non-transparent curtain walls perpendicular to the main axis of the plant are made of the self-supporting pole-bot façade aluminum system.