CAMP'S (A Contemporary Abbey for the Production of Mustard and Pickles)

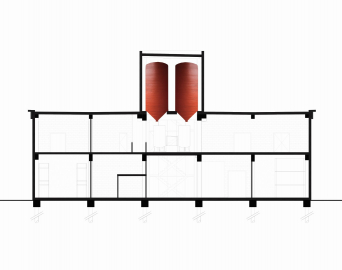

A building for mustard and pickles according to an innovative abbey principle. The low budget leads to a condensed concept. It's language is simple, sacral and reminiscent: a thought of a phenomenon from the past. Within the vision “design as craftmanship” the production was re-invented from horizontal to vertical, with the mustard tower as an acme.

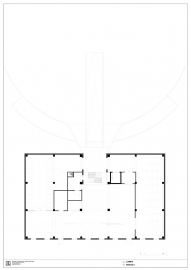

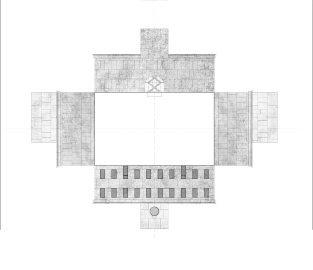

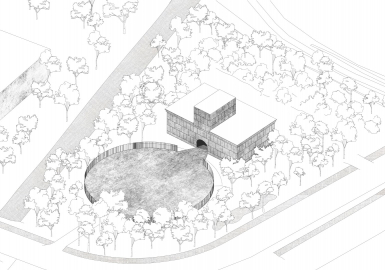

The site is located on the outskirts of Oudenaarde, in a zone for small industry on the edge of a nature reserve. Other buildings occupy their property by fencing on the field boundary, but this site remains open.The mirror axis of the building and the concrete arena runs perpendicularly to the nearby St Walburgachurch. Outside this concrete perimeter, nature grows lush and minimizes the occupancy of the building.The size of the arena is determined by the turning circle of the largest truck. The arena will be publicly opened as a polyvalent event square for the community. The façades literally translate the inside and the production. The central gate in the building reveals itself as a gaping hole in the massive façade that consists of a rhythmic set of concrete panels. The front accommodates storage that is UV sensitive and the back is completely cut-out in favor of the workspace.

In order to save costs, we have taken up the challenge to create poetry using standard prefab elements of an industrial builder. The elements themselves are not unseen but by precisely combining the elements in a specific way we arrived at an innovative whole.

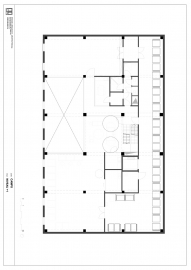

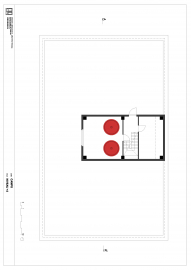

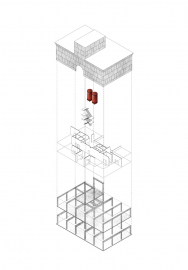

The shape of the building follows the production process. The old horizontal process was physically demanding and dangerous for food safety due to the use of pumps. We turned the proces into a pump-free, gravity system. The tower in which the silos are housed gives the building a specific face. The great weight at the top of the building set the tone for the concrete architecture that could absorb these forces and at the same time resist the amount of acid vapor in the production. Most buildings for food production are closed according to the box-in-box principle. This, however,ensures that the people who work there don't have contact with the environment, the seasons, the daylight,..We created an open space. The building must comply with the standards of food safety whereby the hygienic and non-hygienic zone must be strictly separated. This central helix staircase resolves this problem and forms the DNA of the building.

We have given the production much greater efficiency through the vertical process. This allowed us to reduce the footprint and the entire layout of the building to a very sustainable whole with a good energetic level in relation to the cost. The building is placed on a grid of 6 by 6 meters where a maximum standard production size for the sandwich panels ( concrete – isolation – concrete ) can be maintained.The combination of the prefab elements, and their continuous visibility (both inside and outside), ensures that the building is not only easy to read, but also allows it to be easily 'stripped' from the inside. We build a timeless carcass to ensure that the building can change its function in the future without complication, whereby the concrete basic elements almost always ask for their preservation. Sustainability in its construction form. Aesthetic and efficient. By using standard prefabricated concrete in the façade, we also show the beauty of the natural shades that arise spontaneously. We encourage the evolving and discolouring of concrete as material. The building gets stronger by getting a patina.