15 Clerkenwell Close

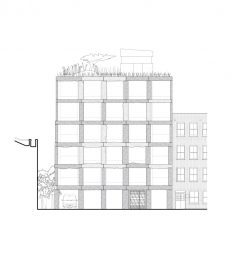

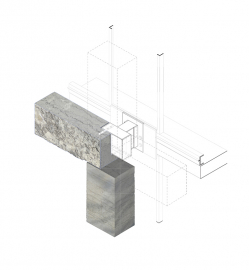

Deploying a trabeated limestone exoskeleton in its natural finish the design aims to unify structure and reference to local heritage as architectural expression and in turn remind us that the etymology of all architectural languages is still driven by their material’s structural, visual and tactile properties.

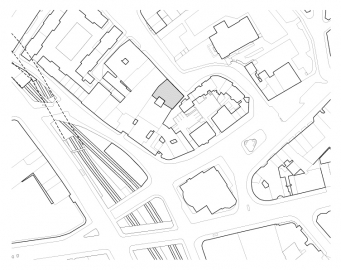

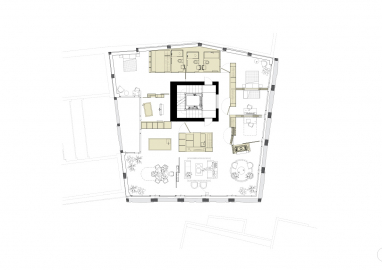

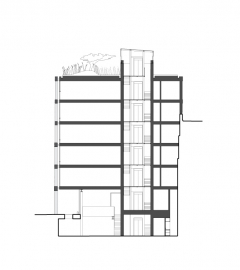

C11th Norman barons established an Augustinian monastery on the site outside the old London city walls. Dissolved by Henry VIII, it was used as a palace before cleared by Oliver Cromwell to make way for his residence, also raised after his death and replaced with merchant properties. Becoming semi industrialised, William Morris established a proto-socialist newspaper for which Marx wrote and Lenin later used the machinery for his paper Iskra. Mid-C20th saw almost 70% of structures replaced with poor quality pastiche misguiding the casual observer of the actual heritage and authentic architectural languages. This design aims to use the Norman’s very original building material and technology with some introduction of current techniques for thermal isolation and so on. Eight apartments and two floors of office are accommodated across seven floors.

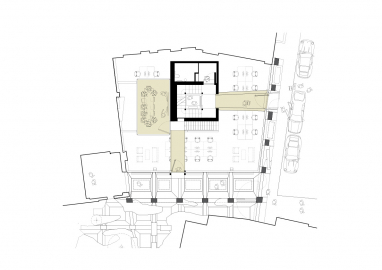

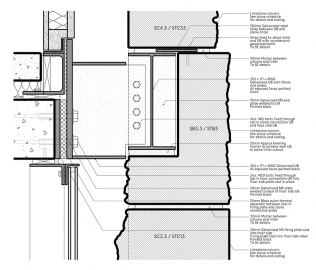

Stone as an actual full supporting structure has not been used in the UK for around 100 years. While still common in France for instance on the whole the world and developing economies especially have bypassed it using steel and concrete out of expedient convention. There is more of it than we can ever use, already processed and fabricated below our feet over millions of years ago. Meaning its carbon footprint is around 8% of the equivalent steel or concrete superstructure when extracted, cut to size, transported and erected on site. Progressive collapse can be overcome by either oversizing stone columns and beams or increasing the strength of slab edges whether timber or another material. How we finish/dress the stone will depend on tastes, here the sedimentary limestone is allowed to express the fossilised coral, ammonite shells and quartz pockets and seams. Additionally the skills of the quarry master’s tools in extracting the stone and the mason’s in cutting and preparing the material are expressed as the hand finished craft of a natural material. At ground level tactile elements in the form of fallen columns and pebble mosaics allude to the specific historical presence.

Engineering software was used to set out load paths and size columns and beams to suit. Counterintuitively corners have almost no load and the top increases to resist window loading. The three inherent quarry extraction process finishes (sedimentary cleavage, drilled and saw cut) form a ‘controlled organic random’ elevation, varying to structural requirement and happenstance of the quarry. Column free interiors allow future flexibility from multiple to single units and residential to office use by removing or altering the oak ‘furniture’ that combine partitions, doors and cabinetry. The need for both ‘green roofs and water attenuation normally requiring a large new basement structure with constant running pumps is combined through the use of four trees whose rootballs absorb 80% of London’s average annual rainfall with the remainder as a buffer for dry years and low lying plants. Reduction of materials and building processes reduced the carbon footprint by 40% and construction cost by 25%. Energy loads are reduced by controlling the exoskeletal distance to act as solar shading, super insulating and triple glazing the envelope.