Cork House

Cork House is the first building of its type, made using a radically simple new form of solid plant-based construction. It shows how we can rethink construction in relation to whole life environmental sustainability in a way that can open up new possibilities for architecture and give unexpected and delightful results.

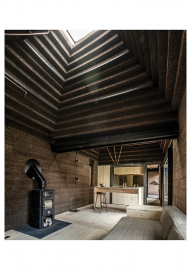

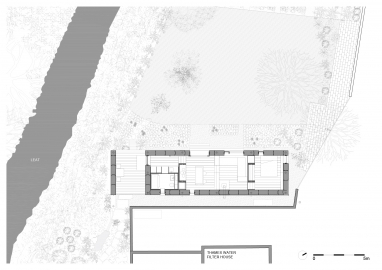

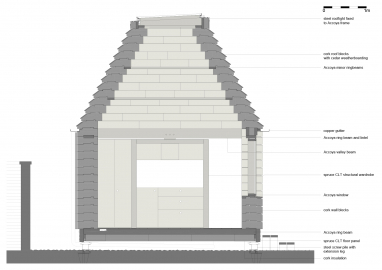

Cork House is a prototype for a new construction system. It is situated on a small island in the Thames, and is positioned to form a gateway between two gardens. Built using expanded cork blocks from Portugal, the architectural form is new and yet familiar. With its five corbelled pyramid roofs, it is an investigation into the architectural language of cork stereotomy, a progressive reimagining of historic dry-stone structures in pure compression. The sheltering interiors are organised spatially according to the rhythm of its roofs, with each pyramid ascribed a specific domestic function. Inside the house the exposed cork captures light and shadow and creates a rich, evocative sensory environment in relation to touch, sound and smell. The house is cooled passively by stack ventilation in summer, and the thick cork walls create a strong sense of warmth and protection in winter.

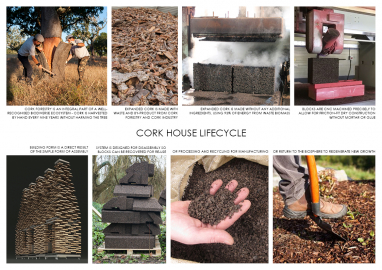

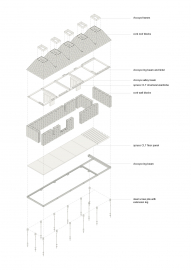

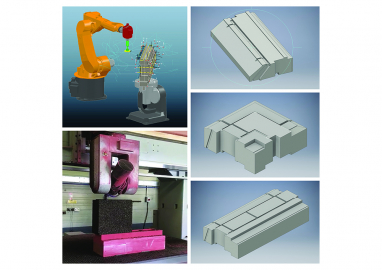

The aim of this project was to rethink the wall, and the building envelope more broadly, by developing a radically simple new form of construction. Most contemporary forms of construction tend to meet current performance requirements through an aggregate approach with many divergent components and layers. This adds complexity at every stage of a building’s life cycle, and often ends in destructive demolition because the building is too costly to disassemble. The intention here was to develop a building with outstanding whole life performance, using plant-based materials in a system that is easy to assemble, low energy to inhabit and easy to disassemble at the end of its life. Cork House uses an evolved version of a cork construction system developed from 2015 to 2018 by a research team including The Bartlett School of Architecture UCL, University of Bath and Arup, and part funded by Innovate UK and EPSRC. The research included laboratory tests for structure, fire and weathertightness, and involved the building of two prototype structures. The research also developed a method of off-site prefabrication, using CNC milling to produce the range of block types required.

The distinctive tectonic form of Cork House is the result of a whole life approach to environmental sustainability – where Form Follows Lifecycle. Cork is harvested from biodiverse forests in Portugal. Expanded cork blocks are made with granulated waste and by-product from cork forestry, which is cooked in autoclaves with no added ingredients. The blocks are then CNC milled with a tongue and groove geometry to give a precise interference fit that also contributes to air- and watertightness. The cork blocks are combined with engineered timber components to create a prefabricated kit of parts, which is assembled on site by hand without the use of mortar or glue - a bit like giant, plant-based Lego. The result is a building that is low energy to inhabit, with no routine maintenance of its structure needed. At the end of building life, it is equally easy to disassemble for reuse or recycling of its components. The cork is uncontaminated and so can simply be returned to the biosphere when it falls out of human use. According to a Whole Life Carbon Assessment to BS EN 15978, the house is embodied carbon negative at completion, with exceptionally low whole life carbon of 618kgCO2e/m2.