The Macallan Distillery and Visitor Experience

The Macallan distillery and visitor experience is set into the estate that has been making whisky since 1824. The building reveals the production process and welcomes visitors while remaining sensitive to the surrounding countryside. In 2019 it won the RIAS Doolan Best Building in Scotland Award and was shortlisted for the RIBA Stirling prize.

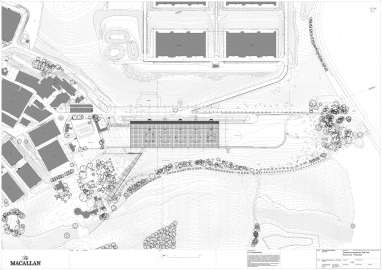

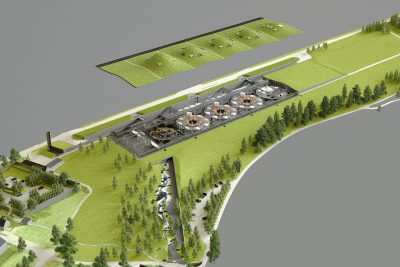

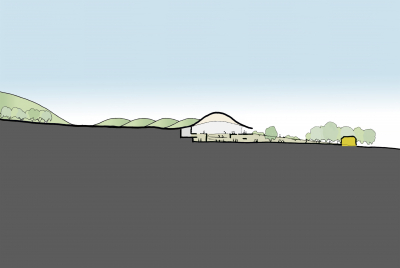

The distillery is set into the landscape of the 18th-century Easter Elchies manor estate in Speyside Scotland.

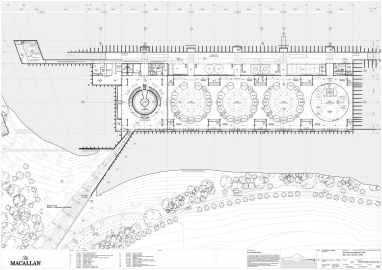

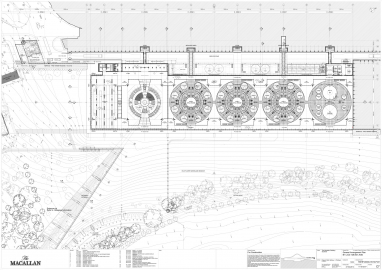

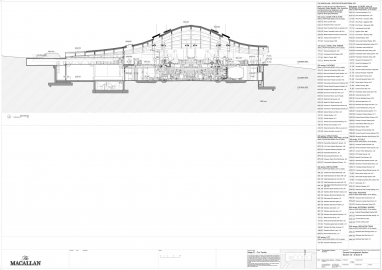

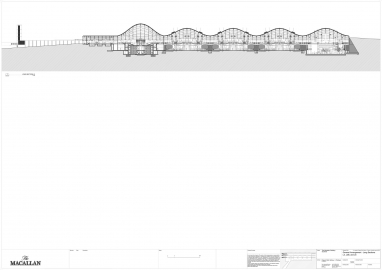

Internally, a series of production cells are arranged in a linear format with an open-plan layout revealing all stages of the whisky production process at once. These cells house equipment in a circular configuration and are reflected above the building in the form of the gently undulating roof, formed by a timber gridshell.

The visitor experience starts with an exhibition and gallery area, before progressing through a sequence of spaces that follow the production story of the whisky. Natural materials: local stone, timber and the living meadow roof – as well as the grass-covered peaks rise and fall from the sloping contours of the ground, evoke the environment and ancient Scottish earthworks.

The concept is a contemporary distillery that embodies Macallan’s international brand, the new building provides a facility capable of increased production while allowing for easy expansion in years to come.

The project is an advanced manufacturing facility that produces a highly flammable product which shares the same roof as the busy visitor experience centre. It is an exemplar of integrated design which has demanded highly skilled construction. Between the visitor centre and the process hall is a two-hour fire rated wall, constructed of cantilevering steelwork supporting un-rated glazing. An integrated drencher system is included within the intumescent painted steelwork to protect the glazing.

The concept evokes the environment and ingredients of whisky production and provides an atmospheric journey for visitors through its use of materials, timber, living meadow roof, and landscaping. Steam generated from an adjacent forestry commission biomass plant provides the primary energy source for distillation. Low-grade waste heat from the production process is captured via a heat exchanger to supply hot water for the visitor centre and underfloor heating.

Steel is an integral part of the building. Steel ring beams and columns support the timber roof, curved steel process tables support the copper stills and discrete steel trusses bridge over the delivery road to provide fire egress and an incoming route for the primary materials used in production

The roof is one of the most complicated timber structures in the world, comprising 1,800 single beams, 2,500 different roof elements, and 380,000 individual components, almost none of which are equal or the same

Glulam beams are placed where their lightness and bending capacity can be demonstrated. In areas of additional shear stress, LVL is mobilised to assist. The domes of the timber grillage sit on a steel tension ring, which in turn is supported by inclined steel columns — these bear the resulting thrusts into the concrete shear walls and thus into the ground. By separating the roof from the earth, lateral pressures are relieved, allowing the roof to ‘float’ above.

The project is an exceptional example of production and logistics using offsite construction, and uses natural and sustainable materials in the 13,000m2 wildflower meadow timber roof.