Scania Industrial Complex

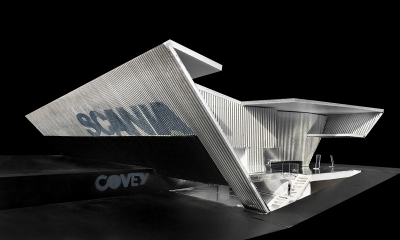

The requirement to create a building of an imposing nature to act as an advertising element as well as a functional container. This allowed us to propose a single volume, with a single material, allowing the building to dominate its landscape whilst meeting all its objectives in a cost effective manner.

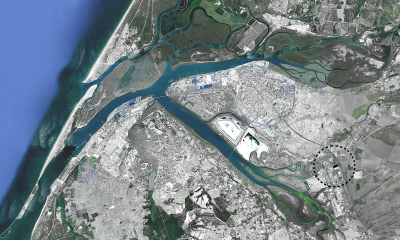

On the right bank of the mouth of the Rio Tinto, on a plain adjacent to the Nicoba marshes, extends the largest industrial estate in the province of Huelva. At its gates, on a bordering plot between the urbanized and the emptiness, the Swedish truck manufacturer Scania decided to place its new facilities in the region.

The main qualities of this location were the vast infrastructure that surrounds it, offering the opportunity of creating a far reaching and powerful visual volume, where architecture becomes an advertising element as well as a functional container.

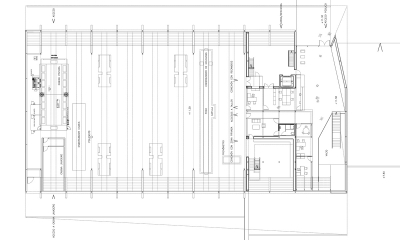

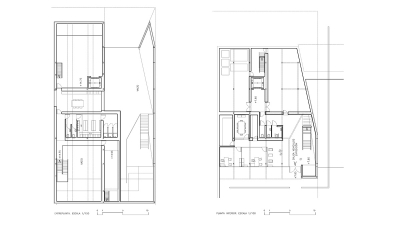

The requested program had different demands. On the one hand, a large diaphanous, horizontal and zenithal illuminated space for the set-up of trucks. On the other, an exhibition and commercial area at several levels with natural light for administrative space. The client also requested a building of imposing character.

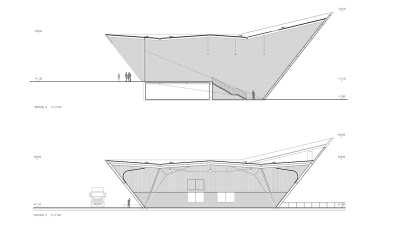

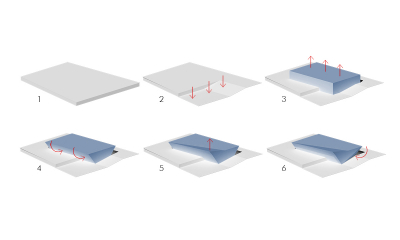

The latter condition led us to encompass the different parts of the program in a single volume, with a single material, trusting that this decision helps to fill the gaps that a relatively small program creates. In this way, the steep slope of the plot was used to help meet this interest, creating a large esplanade in front of the access area, delaying the position of the retaining wall and also superimposing the program vertically on the head of the building; all to increase the volume by increasing the height from 10 meters in the rear area to almost 20 meters in the main west corner.

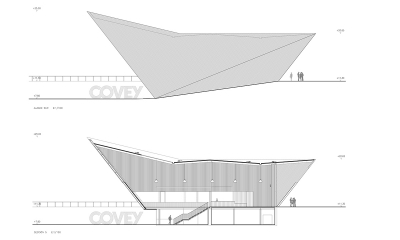

This set of volumetric needs was solved by an inclination or abatement of the facade planes until reaching almost 45º, in a gesture that is continuous, and begins symmetrically, and is modified for the specific conditions of each orientation. This prolongs the threshold between inside and outside with no added elements, hence increasing the area of the building protected from the weather.

To achieve this it was decided to use a structural system of beams and pillars bent and post-tensioned, a hybrid scheme that stiffens the structure until no more bracing elements are needed than the main porches of the building. A direct and precise construction system of dry joint metal coatings were also used, materials belonging to industrial rhetoric, but also to the motor world, seeking a natural dialogue with the true users of the building.

The goal of architecture is to improve human life. We fear in industrial parks this central concept is being neglected, with a negative consequence to workers and participants of this environment.

Industrial parks are not the battleground of vanguard architecture, nor will it be in the future. However, an improvement in the surrounding architecture in a cost effective manner we believe is possible through a closer collaboration between architects and engineers, which allow the latest technology to be infused with functional and creative design possibilities that can improve the landscape and spirit of the local community.

In this project a small area of land on a challenging, inclined plot was allowed to exploit its privileged location to become a powerful and imposing beacon through the selected shape and materials chosen only discovered through continuous dialogue with a number of engineers. It is an unconventional solution in industrial architecture, representing an interesting solution both structurally and aesthetically due to its slenderness and lightness, and it is also a competitive economic solution.

The industrial building for Scania shows an innovative structural solution consisting of a "Skelsion" structure consisting of the above mentioned pre-stressed steel frames of beams and pillars. It is an unconventional approach in industrial architecture, representing an interesting solution both structurally and aesthetically due to its slenderness and lightness, and it is also a competitive economic proposal. The design of the structural geometry was carried out by an iterative process considering the interactions between the different pre-stressed elements and the erection sequence. The result provides the required stiffness to the structure to resist all the forces thanks to the pre-stressed bracings, whilst achieving an aesthetically pleasing result.