CopenHill

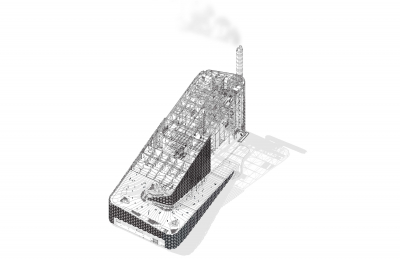

CopenHill is a multifunctional, social, and cultural waste-to-energy plant where waste is transformed into heat and power for all citizens of Copenhagen. The tall, sloped roof doubles as a year-round artificial ski slope, hiking trail, and climbing wall open to the public.

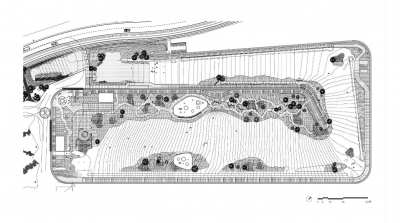

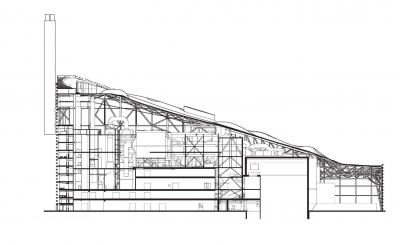

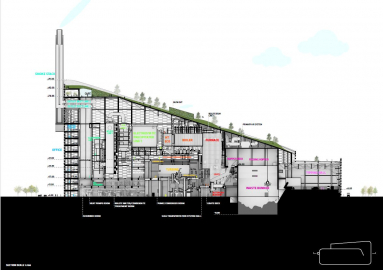

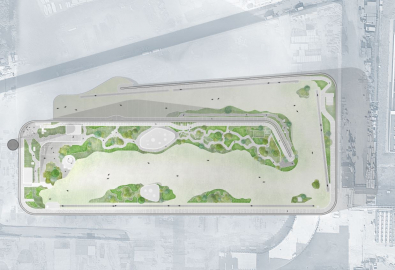

CopenHill is the cleanest waste-to-energy plant in the world, and is topped with an urban recreation center and environmental education hub, ultimately turning social infrastructure into an architectural landmark. The internal volumes of the plant are determined by the positioning and organization of its machinery in height order, creating a sloping rooftop for a 9,000m2 ski terrain. Visitors reaching the summit feel the novelty of a mountain in an otherwise-flat country. Non-skiers enjoy the rooftop bar, cross-fit area, climbing wall or highest viewing plateau in the city before descending the 490m tree-lined hiking and running trail within a mountainous terrain.

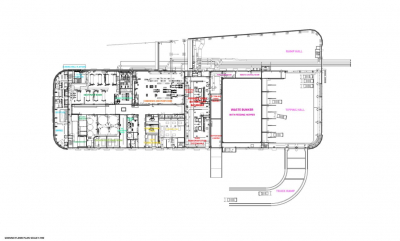

BIG participated in a design competition to replace a 50-year-old waste-to-energy plant in Copenhagen. Thought the brief did not require architects to consider a social benefit for the city, this piece of infrastructure that is almost always separated from the city, becomes the center of social life, and a landmark for a sustainable future. CopenHill aligns with Copenhagen’s goal of becoming the world’s first carbon-neutral city by 2025. The plant converts 440,000 tons of waste annually into enough clean energy to deliver electricity and district heating for 150,000 homes, producing 25% more energy than the original plant from the same amount of waste. CopenHill harvests local resources, rainwater, daylight and natural airflows. The 10,000m2 green roof includes 400 plant species, addresses the challenging micro-climate of an 85m high park, rewilds a biodiverse landscape and adds social spaces for all species.

CopenHill’s continuous façade comprises 1.2m tall and 3.3m wide aluminum bricks stacked like gigantic bricks overlapping each other. In-between, glazed windows allow daylight to reach deep inside the facility, while at night the façade is illuminated. Larger openings on the southwest façade allow daylight into workstations on the administrative floors. On the longest vertical façade, an 85m climbing wall is installed to be the tallest artificial climbing wall in the world. There is a glass elevator behind the climbing wall, so that climbers are visible from the inside, and climbers can look into the factory. The surface of the ski slope is designed with Noveplast, used by pro skiers use for training in summer months in southern Europe. The plant structure is made with a combination of concrete and 6,000 tons of steel, and is the winner of the European Steel Structure Award.