Educan - School for Dogs, Humans and Other Species

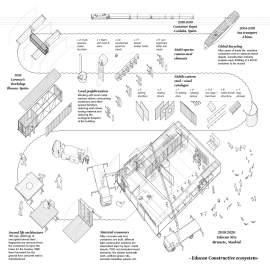

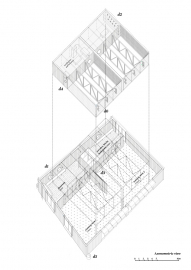

Educan is an educational multi-species architecture where dogs, humans and other species coexist and learn together. The project reflects on how agricultural buildings, usually relegated to the margins of the discipline, can become exceptional testing grounds for exploration and innovation.

Three humans, two belgian shepherd dogs, one owl, five families of swifts, six of krestels and twenty sparrows are companion species. They coexist and learn together in this building, located between croplands, 30 kilometers west from Madrid. Immersed in a rural landscape altered in the last decades by an intense urbanization process and the use of pesticides in agriculture, this project addresses how architecture, through sensitive production processes, can contribute to recover the environmental conditions of a rural ecosystem.

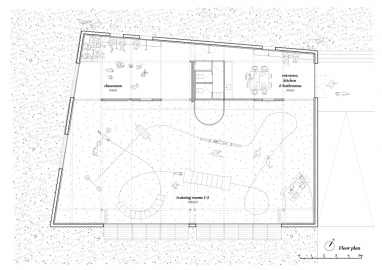

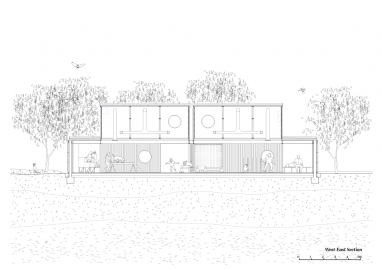

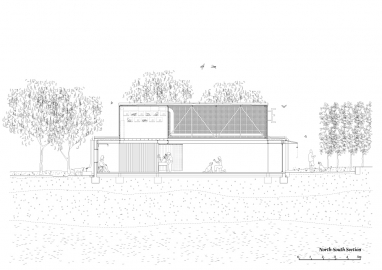

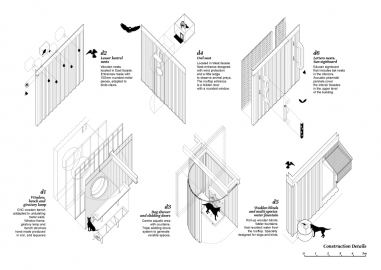

The building is a multi-species design. While pairs of dogs and humans practice together in the training rooms, birds nest in the facades on the upper floor. They feed on rodents, maintaining a balance with crops, other plants and pollination cycles. Bats, which inhabit the facade letters, feed on insects, including mosquitoes that carry canine diseases. Lately, sparrows have joined this self-regulated ecosystem in an unplanned way, nesting in the circular holes of the containers.

Non-humans are the center of the design. The floor, usually designed for humans wearing shoes, is now adapted to the softness of dogs footpads —and covered with removable rolls of artificial grass. The interior windows are elevated, allowing higher views that avoid doggy distractions. The voice becomes bark, and the interior surfaces are coated with pyramid shaped acoustic panels that minimize noise and reverberation. Meanwhile, in the exterior, rainwater is collected in large watering holes for dogs and birds.

Material crossovers are explored in this building, combining different construction techniques and systems. From a material ecology that reduces waste by reusing maritime containers, to the adaptability and thermal inertia of in situ concrete —moulded with plates recovered from metal cuts—. From the optimization of industrialized metal sheets to the precision of CNC-cut laminated wood joints. From the industrial standardization of the 40'hc containers to the artisan locksmith work that allows customized assembly or new elements such as bench legs, lamps or large sliding doors that open and close spaces. From automated air conditioning systems, to manual bioclimatic control elements such as perforated shutters or roller blinds. From the weight of the concrete wall to the lightness of dry-assembled elements. Overall, the project addresses an investigation on how minor architectures are scenarios for constructive exploration and innovation.