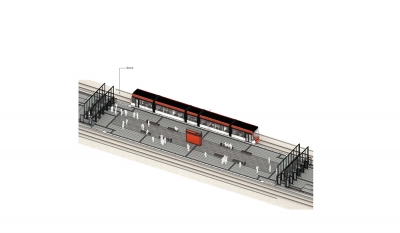

Haukeland Bybanen (light-rail train) station

The goal for the Haukeland Station has been to reconcile high urban ambitions with complex underground technical solutions, with a particular focus on passenger safety and perceived security. The station connects the city's largest workplace, Haukeland University Hospital, and the health clusters in the area with the light rail network in the city.

The goal for the Haukeland Station has been to reconcile high urban ambitions with complex underground technical solutions, with a particular focus on passenger safety and perceived security. The station connects the city's largest workplace, Haukeland University Hospital, and the health clusters in the area with the light rail network in the city.

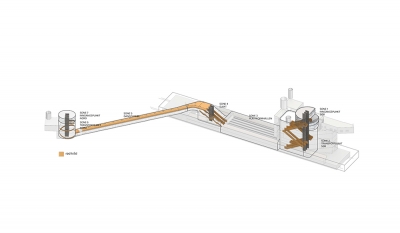

Our design concept for the facility has been to guide passengers through a few but very different spatial experiences, characterized by a clear yet varied design, emphasized by changing material choices for each volume.

Actual safety for users is underground is mandatory, but perceived safety is just as important for a good user experience.

Key aspects for us have been:

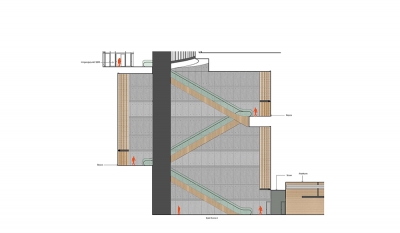

Overview: to see far and be prepared for unwanted events as early as possible.

Orientation: ensuring that the journey underground is not confusing, so that passengers do not lose their sense of direction.

Simple volumes: ensuring that there is good visibility and predictability at all times, without blind spots.

Lighting: ensuring that the artificial light complements the architecture and emphasizes that natural light from above, is the most important guide to the exits on the ground.

Acoustics: ensuring that the acoustic experience is so good that noise and reverberation are not bothersome despite large volumes and a strong railborne noise source.

Art: integrating it with the architecture, emphasizing the spatial experience of variety, while also conveying coherence, connection and colors.

Thorough mapping of ground conditions, monitoring of deformations, and injection of concrete into the rock have been crucial to enable the extensive concrete work that has been carried out.

In the large shaft escalators rise 10 meters in three sections. There are a total of 6 elevators, and the tallest elevator shafts are 42 meters high. 7,000 m³ of concrete and 700 tons of reinforcement have been used. The facility has 2,500 m² of visible concrete surfaces. All concrete is exclusively produced with low-carbon, class A.

All other materials have been selected based on properties that provide sound absorption class A with a fire safety class at the second highest level (A2-s1,d0)

The total cost has been 950 million NOK.

The design is CEEQUAL certified as "very good", and project's execution achieved BREEAM certification "Excellent", with the highest score achieved in Norway to date.