Extension to Raubergstølen Mountain Lodge

Extension of resturant at Raubergstulen resort

Raubergstulen is a hotel placed close to Norway’s highest mountain, Galdhøpiggen. The area also has a large number of other hiking trails than the one going to the top og Galdhøpiggen, making the hotel an ideal base camp for day trips. The number of visitors to the hotel has been growing, making it necessary to expand the restaurant. In the vicinity of the hotel there is an old pine forest, with many trees around 250 – 300 years old. Due to the quality of the soil a large proportion of the trees have spreading branches, making them less usable for traditional construction purposes. Typically the journey of mature trees from the forest to the construction site as building material is complex, involving a number of industrialized processes. After the trees have been chopped down and the branches are stripped off, the logs are transported to the nearest road, loaded on trailers, brought to one or more sawmills, split up and the useable parts of the logs are further spilt up and dried. Then the lumber is distributed to wholesalers, who distribute the lumber to the shops selling the materials. Only then the material is transported to the building sites.

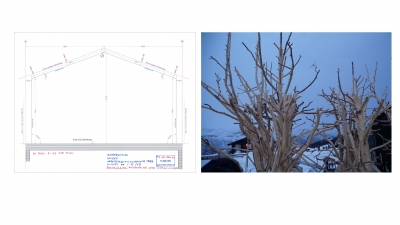

We wondered if it would be possible to avoid this long chain by transporting trees, with the branches intact, directly to the site just a few hundred meters away. There is a old pine forest close to the hotel. After evaluating some alternatives, it became clear that using local wood would have many positive effects: low transportation costs and correspondingly low carbon footprint and activation of local resources, both equipment and expertise, as well as very low wastage.

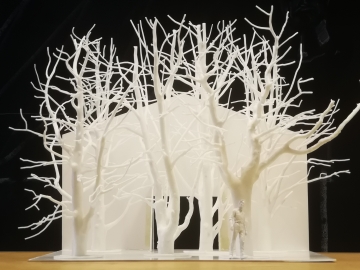

After a closer assessment of the trees in question, it turned out that the wood is not only late-grown primary pine, but that it also has an extensive and rich branch network, not unlike that seen in larger deciduous trees such as oak and beech. Quite quickly, a hypothesis emerged that, due to the proximity of the construction site, within one kilometer, the trees could be transported up without removing the branches. The idea behind this was to retain existing nodes and branches and use them constructively. In this case, the proximity to the construction site makes this possible.

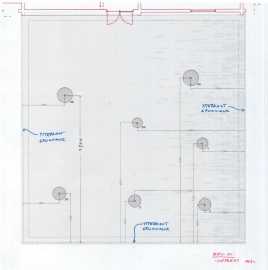

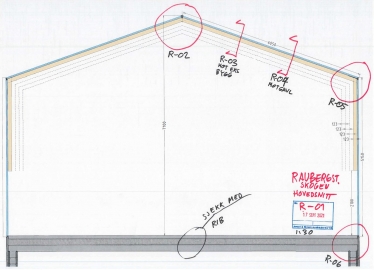

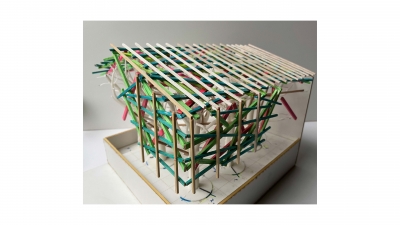

Seven trees were identified during a sitevisit in December 2020. These were pruned so that branches smaller than 50mm were sawn off and then the trees were sawn down and transported to the construction site by a forestry machine. To make this process as efficient as possible, all seven trees were accurately scanned by a drone. The data files from the scan are converted into files that can be 3D printed. All seven trees are sinteprinted at a scale of 1:33, with a base plate so that they stand without support. These model trees were placed on the floor of the model, and we could rotate the trees and see how they would best fit into each other. All trees had at least two points of contact with neighboring trees to establish a rigid static system. We then used a laser plane to cut the branches exactly within the canopy volume. From the chaotic pattern formed by the ends of the trees, four layers of aligned timber are established, from chaos to a modular outer layer, so that all the cut branches are connected in a rigid cage with a precise shape. This cage forms the support for the glass roof and walls. On the site the contractor used the model as the primary instruction instead of conventional drawings.