Cyclops Cultural House

The Cyclops cultural house is a unique project within todayŽs industrial architectural tradition. The very conditions of the project have required specific architectonical solutions the client being a cultural association with many members and a need for much space, but also a very limited budget.

THE OUTSETS

1. One of the projectŽs outsets was to have the house built by volunteers, i.e. the associationŽs members, who have no former experience of construction work. The project was organized through workshops, with some help from mentoring professional constructors.

2. The associationŽs previous house was burnt down by neo-Nazis - most likely due to the Cyclops anti-racist work. When it was time to re-build the house, fire safety was hugely important. Therefore the building was designed to mimic a turtle with its protecting shell.

3. The aim was to create a colorful and happy house to reach out to the local society.

SLOW ECONOMY

The most expensive denominator in an industrial construction project is the construction worker. This is normally compensated through the purchase of ready-

made parts that are installed with cranes. Being manufactured in factories where the cost of labor is lower, these parts are viewed as inexpensive. But when the cost of labor is zero, the material is no longer inexpensive, but the main cost. And in this case it is better to manufacture everything yourself.

Instead of timesaving solutions with somewhat of a material cost, you choose a time-consuming solution with a lower material cost. As an example it was more economical to raise the glued laminated timber framing the old fashion way with a rope and manual force, than renting a crane.

In an extended construction project as this, it was not financially feasible to rent a scaffolding. Instead, I designed the houseŽs secondary framing to be just that. The secondary framing is a combination of pre-manufactured products such as scaffolding plates and scaffolding feet with custom designed carrying frames. The secondary framing was designed to constitute the infrastructure in the finished building, holding its staircases and hallways. The frames, higher and wider than the standard frames, also linked the floors and created a handicap-friendly space, enough for the fire escapes. Finally it is also carrying the polycarbonate façade.

The main structure is created from glued laminated timber and is carrying the second floor and the roof. Being strong in relation to heat, but at the same time burnable, the structure is drawn in from the façade. If a fire-bomb like the one demolishing the first house hits the façade the secondary structure would be damaged but the fire would never reach the main structure. And the main structure would not risk to collapse as a result of the heat.

`A POOR MANŽS ECOLOGYŽ

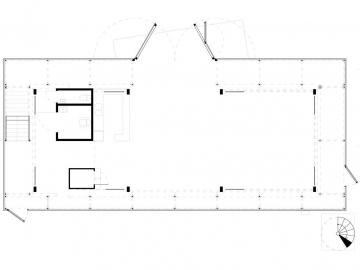

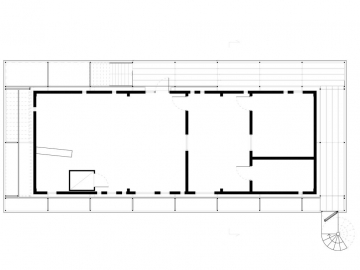

Following a philosophy that focuses on lowering your ecological footprints by adapting to the climate we live in. The associationŽs budget didnt allow a grand house if entirely heated. The house is shaped around a warm center, the box. The shell is colder, heated mostly by waste-heat from the core.

SIZE

Site: 1.400 m²

House footprint: 200 m²

Gross floor area: 459 m²